The next generation

monopile foundations

for offshore wind turbines

Manufacturing, design and handling challenges

The Urge to Scale Up Offshore Wind

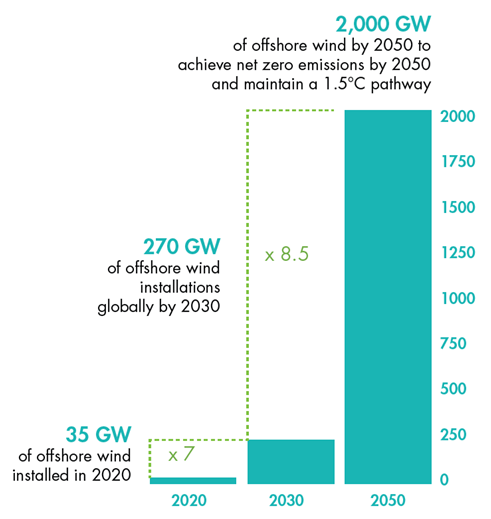

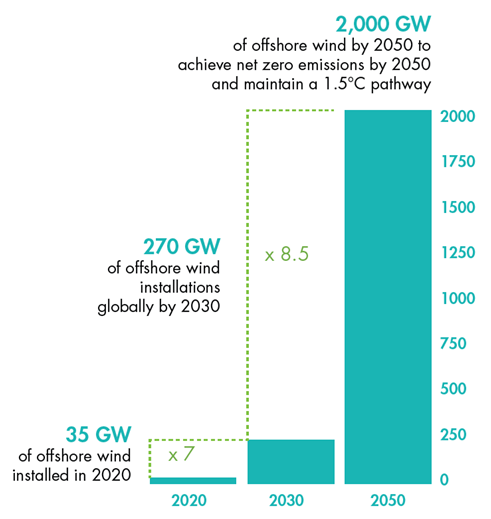

Offshore wind production has grown exponentially over this century, but so far we have just witnessed the tip of the iceberg. With Climate Change pressing ever more and decarbonization becoming a rising policy priority in national and supranational agendas across the globe, offshore wind power will play a vital role in the transition to net zero. Before the end of this decade, it is expected to experience a 7-fold increase. Besides, if we are to remain on track with the Climate Neutrality target, by 2050, we should multiply by fifty today´s offshore wind installations.

Closing the Offshore Wind Gap by 2050. Source: GWEC

Pioneers in Offshore Wind Engineering

BOSLAN is a Spanish company with over two decades of experience offering highly specialized technical, engineering and consultancy services. Headquartered in Bilbao, it has permanent offices in 9 countries and 750+ employees. It is currently running projects in 30 countries.

In the last few years, Boslan has been in charge of the development of state-of-the-art offshore wind farms across the globe, covering the construction project cycle in projects such as Wikinger, Baltic Eagle, East Anglia One and Saint-Brieuc.

Boslan´s practical and technical know-how in the design, manufacturing, assembly and handling of fixed foundation structures has made us a preferred partner for developers who need to confront the technical challenges of the next generation monopile foundations.

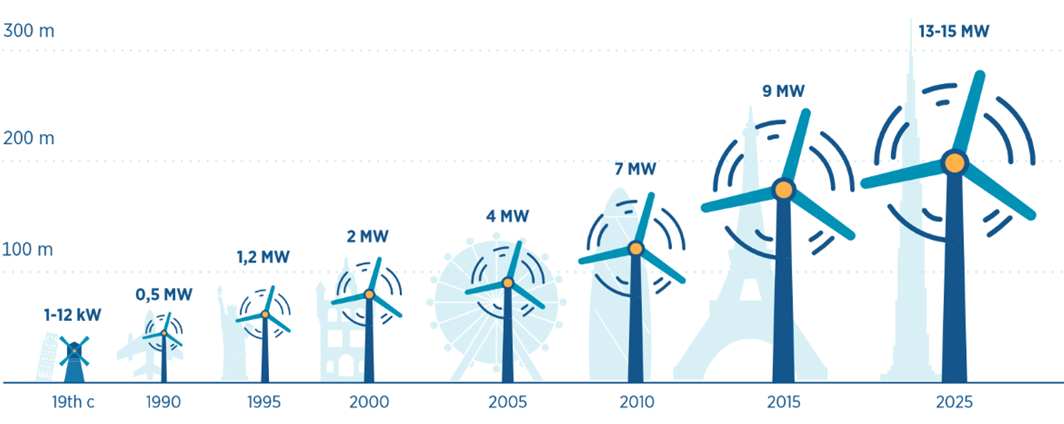

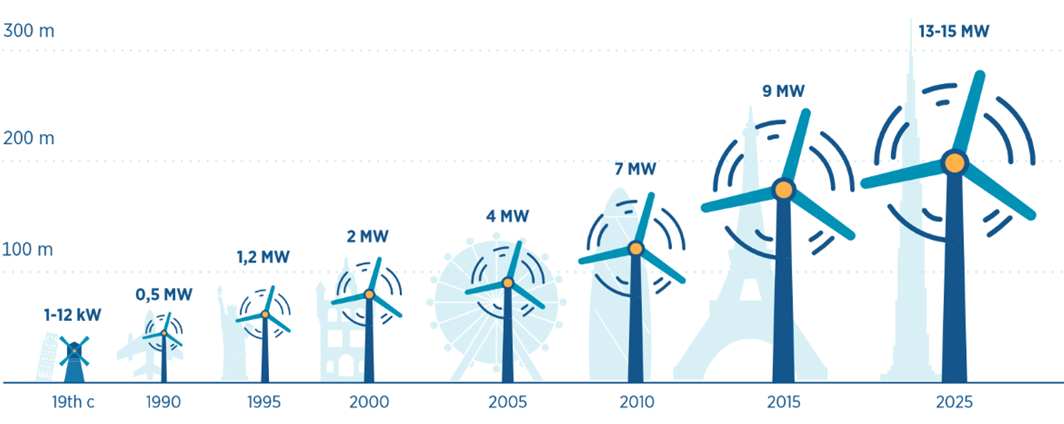

Citius, Altius, Fortius

The technical challenges are colossal, as we need to go bigger, further and deeper into the ocean. The world´s first offshore turbine farm, installed 30 years ago at Vindeby (Denmark), had turbines of only 450kW, with a rotor diameter of 35m, merely 2 km from shore and a maximum water depth of 4m. Before the end of this decade, we are likely to witness wind turbines of 20MW and rotor diameters beyond 250m, with wind farms 200Km far from the shore and water depths beyond 60m. These figures seemed science fiction merely a few years ago… and they still do!

Evolution of Wind Turbine Power and Rotor Diameters over Time. Source: IRENA

Towards XXL Foundation Structures

These monstruous turbines also imply larger supporting structures, and manufacturers are already working on the next generation of fixed foundations: XXL Monopiles with lengths up to 120m. These ultra-large structures require greater diameters and weights beyond 2,000 tonnes. They create tremendous logistical challenges in the manufacturing, handling, transportation and final assembly processes.

Current manufacturing standards are no longer valid as we push the technological boundaries. If we held the D/t ratio constant, a 25% increase of the monopile diameter (e.g. from 8m to 10m), would approximately double its weight, and a 50% increase in the diameter (e.g. from 8m to 12m) would triple it. Hence, weight reduction becomes imperative in the design of the next generation monopiles, and recent studies suggest that slenderness ratios up to 160 could be feasible. To prevent plastic deformation and damage when handling the cans, we need to rethink the whole fabrication process, including the supports design during the manufacturing, transport, storage and assembly.

Boslan

A Key Engineering Partner in Fixed Offshore Foundations

Over the last few years, Boslan has developed a unique experience on fixed offshore wind turbine foundations, spanning various engineering disciplines at different manufacturing stages, including Jacket and Substation Design and Calculation, Civil and Electrical Works Supervision and Management, QA&QC, Testing and Commissioning, and Health and Safety.

Boslan´s flagship wind farm projects include the following:

✓ Wikinger Project (2017) – Offshore wind farm that supplies 350 megawatts (MW) to the German power grid. Seventy jackets (each weighing 620 tonnes) have been manufactured by Bladt Industries in Lindo (Denmark) and Navantia (Fene, Spain). Windar and Navantia have manufactured 280 piles in Spain, measuring 40 meters in length and 2.5 meters in diameter.

✓ East Anglia One (Start date in 2020) – Offshore wind farm with presence in the UK (North Sea) with a capacity of 714 megawatts (MW). 102 jacket type foundations were manufactured by Navantia (Fene, Spain), Lamprell (UAE) and Harland & Wolff in Belfast (Ireland). Piles were manufactured by Windar in Avilés (Spain).

✓ Saint-Brieuc (Start of the operational phase expected in 2023) Currently under construction, this 496 MW offshore wind farm will be close to Saint Brieuc Bay (France). Navantia-Windar is manufacturing 62 jackets at Fene (Spain). Windar has manufactured the piles in Avilés (Spain). In line with the fabrication strategy adopted by the foundation’s manufacturer, Boslan is present at different locations in France and Spain, covering various roles related to Fabrication, Assembly, Transport, QA&QC and Health and Safety.

✓Baltic Eagle (commissioning date end of 2024) – Baltic Eagle offshore windfarm is a 476MW wind project located in the Baltic Sea, approximately 75km off the coast of Rugen Island, Germany. It will have 50 wind turbines of 9.53-MW of unit power on monopiles, for an annual production of 1.9 TWh. It will meet the needs of 475,000 homes and avoid the emission of almost one million tonnes of CO2 into the atmosphere every year.

The foundations are being carried out by Windar and German EEW SPC. Boslan is supporting the manufacturing process in Avilés (Spain) for 50 transition pieces, as well as other parts in several locations.

Load #12 of Jacket components to be transported from Navantia-Windar manufacturing facilities in Brest (France) for the final assembly in the Navantia facilities in Fene (Spain). Successfully completed last 06.04.2022. Photo: NAVANTIA

Photo: Iberdrola

Baltic Eagle Project. First Transition Piece Fully Assembled. Photo: Windar

The next generation

monopile foundations

for offshore wind turbines

Manufacturing, design and handling challenges

The Urge to Scale Up Offshore Wind

Offshore wind production has grown exponentially over this century, but so far we have just witnessed the tip of the iceberg. With Climate Change pressing ever more and decarbonization becoming a rising policy priority in national and supranational agendas across the globe, offshore wind power will play a vital role in the transition to net zero. Before the end of this decade, it is expected to experience a 7-fold increase. Besides, if we are to remain on track with the Climate Neutrality target, by 2050, we should multiply by fifty today´s offshore wind installations.

Closing the Offshore Wind Gap by 2050. Source: GWEC

Citius, Altius, Fortius

The technical challenges are colossal, as we need to go bigger, further and deeper into the ocean. The world´s first offshore turbine farm, installed 30 years ago at Vindeby (Denmark), had turbines of only 450kW, with a rotor diameter of 35m, merely 2 km from shore and a maximum water depth of 4m. Before the end of this decade, we are likely to witness wind turbines of 20MW and rotor diameters beyond 250m, with wind farms 200Km far from the shore and water depths beyond 60m. These figures seemed science fiction merely a few years ago… and they still do!

Evolution of Wind Turbine Power and Rotor Diameters over Time. Source: IRENA

Towards XXL Foundation Structures

These monstruous turbines also imply larger supporting structures, and manufacturers are already working on the next generation of fixed foundations: XXL Monopiles with lengths up to 120m. These ultra-large structures require greater diameters and weights beyond 2,000 tonnes. They create tremendous logistical challenges in the manufacturing, handling, transportation and final assembly processes.

Current manufacturing standards are no longer valid as we push the technological boundaries. If we held the D/t ratio constant, a 25% increase of the monopile diameter (e.g. from 8m to 10m), would approximately double its weight, and a 50% increase in the diameter (e.g. from 8m to 12m) would triple it. Hence, weight reduction becomes imperative in the design of the next generation monopiles, and recent studies suggest that slenderness ratios up to 160 could be feasible. To prevent plastic deformation and damage when handling the cans, we need to rethink the whole fabrication process, including the supports design during the manufacturing, transport, storage and assembly.

Pioneers in OffShore Wind Engineering

BOSLAN is a Spanish company with over two decades of experience offering highly specialized technical, engineering and consultancy services. Headquartered in Bilbao, it has permanent offices in 9 countries and 750+ employees. It is currently running projects in 30 countries.

In the last few years, Boslan has been in charge of the development of state-of-the-art offshore wind farms across the globe, covering the construction project cycle in projects such as Wikinger, Baltic Eagle, East Anglia One and Saint-Brieuc.

Load #12 of Jacket components to be transported from Navantia-Windar manufacturing facilities in Brest (France) for the final assembly in the Navantia facilities in Fene (Spain). Successfully completed last 06.04.2022. Photo: NAVANTIA

Boslan´s practical and technical know-how in the design, manufacturing, assembly and handling of fixed foundation structures has made us a preferred partner for developers who need to confront the technical challenges of the next generation monopile foundations.

Baltic Eagle Project. First Transition Piece Fully Assembled. Photo: Windar